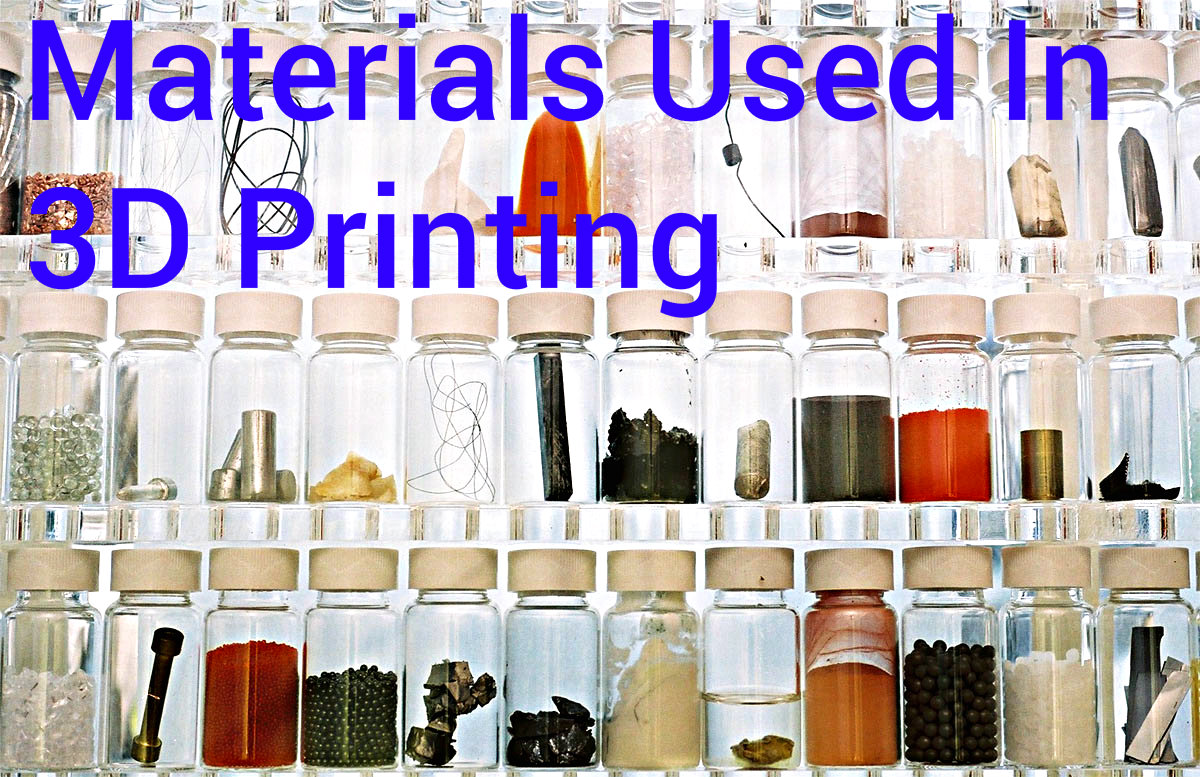

This 3D printer filament comparison guide covers 15 materials used in 3D printing. While the most common materials for 3D printing are plastics, many other materials can be used for 3D printing as well.

Check out our complete 3D Printer Filament Buyer’s Guide 2020 for more information on materials used in 3D printing.

In this article we will cover many of the materials currently used in 3D printing. We have organized the materials into three groups,

- Common thermoplastics available to consumers

- Proffesional and industrial materials

- Experimental materials that are often available only to researchers

3D Printer Filament Comparison Guide

Introduction

Currently, the most popular types of plastic filaments are PLA, ABS, PET, TPU, Nylon, Glow in the Dark, Metal, and Wood. They each have different properties and have different applications.

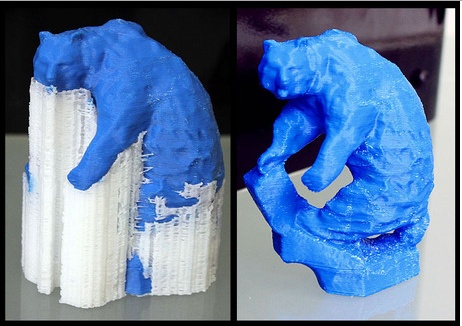

Of these, PLA and ABS are by far the most popular. PLA is a softer plastic that is easy to work with. By soft, we don’t mean that it is malleable.

It is a hard plastic that can be used to print most non-functional plastic objects, such as figurines, jewelry and pencil holders. For functional parts, the current 3D material of choice is ABS.

ABS is much harder than PLA. ABS can therefore be used to create parts for machines, toys for kids, and even medical devices. The only major downside to ABS is that it is a bit harder to work with than PLA.

Before we move on with this 3D printer filament comparison guide, here are a few examples of revolutionary filaments:

- Graphene conductive filament has the potential to bring advanced electronics manufacturing into residential homes where replacement parts for appliances can be created in minutes.

- 3D printers using specialized 3D printer filaments can now create customized medical devices for hospital emergency rooms in real-time.

- Biodegradable algae plastics are replacing plastics that would otherwise end up polluting our natural world.

PETG and Nylon are also growing in popularity. They are both very strong materials and PETG is as easy to print with as PLA.

The fact that PETG has the strength of ABS and ease of PLA, there is a good chance that it will take over as the most popular filament material in the future.

1. PLA Filament

PLA is one of the two most common plastic used in 3D printing. It is non toxic and melts at low temperatures, around 190ºC.

PLA also smells nice and is easy to work with. It’s also hard enough for most applications that aren’t load bearing, such as decorative figurines and jewelry.

2. ABS Filament

ABS is the other of the two most common plastics used in 3D printing. ABS is a particularly strong plastic with a shiny surface finish. It is perfect for functional applications.

ABS is hard, like legos or chess pieces. That means you can make a lot of parts that require high durability, like keyboard keys, light switches, and buckles.

3. Nylon Filament

Nylons are exceptionally good for functional parts. Nylons are super strong and have low surface friction, making them ideal for print parts that rub together like gears.

There are many different kinds of nylons designed specifically for 3D printing, and each of them have different properties. Check out Taulman 3D for the widest range of nylon filaments.

4. Wood Filaments

Wood filament is PLA infused with wood particles, usually a fine type of sawdust. Different types of wood can be used to create different effects when printing with wood filament.

The color of wood filaments can be controlled by adjust the temperature they are printed at. They can also be carved and toasted just like real wood.

5. PETG

PETG has all of the best qualities of PLA with the strength and durability of ABS. That means it can be used to create a wide range of objects very easily.

Because PETG is so easy to work with and so versatile, PETG is quickly becoming just as popular as both ABS and PLA.

6. PVA

PVA is an attractive support material for a few reasons. It is water soluble, so when your print is finished, you can simply dunk the object you printed in tap water and watch the PVA supports dissolve away.

Even though PVA is more expensive than HIPS, HIPS only dissolves in limonene, which is an irritant and not cheap. So a support material that dissolves in water is safer and cheaper to use overall.

7. HIPS

HIPS stands for High Impact Polystyrene. HIPS can be used on its own as a fabrication material or in conjunction with other plastics as a support material in the printing process.

d-Limonene does not dissolve ABS plastic, only HIPS filament, which makes it an ideal solvent to use when 3D printing with HIPS.

Professional 3D Printing Materials

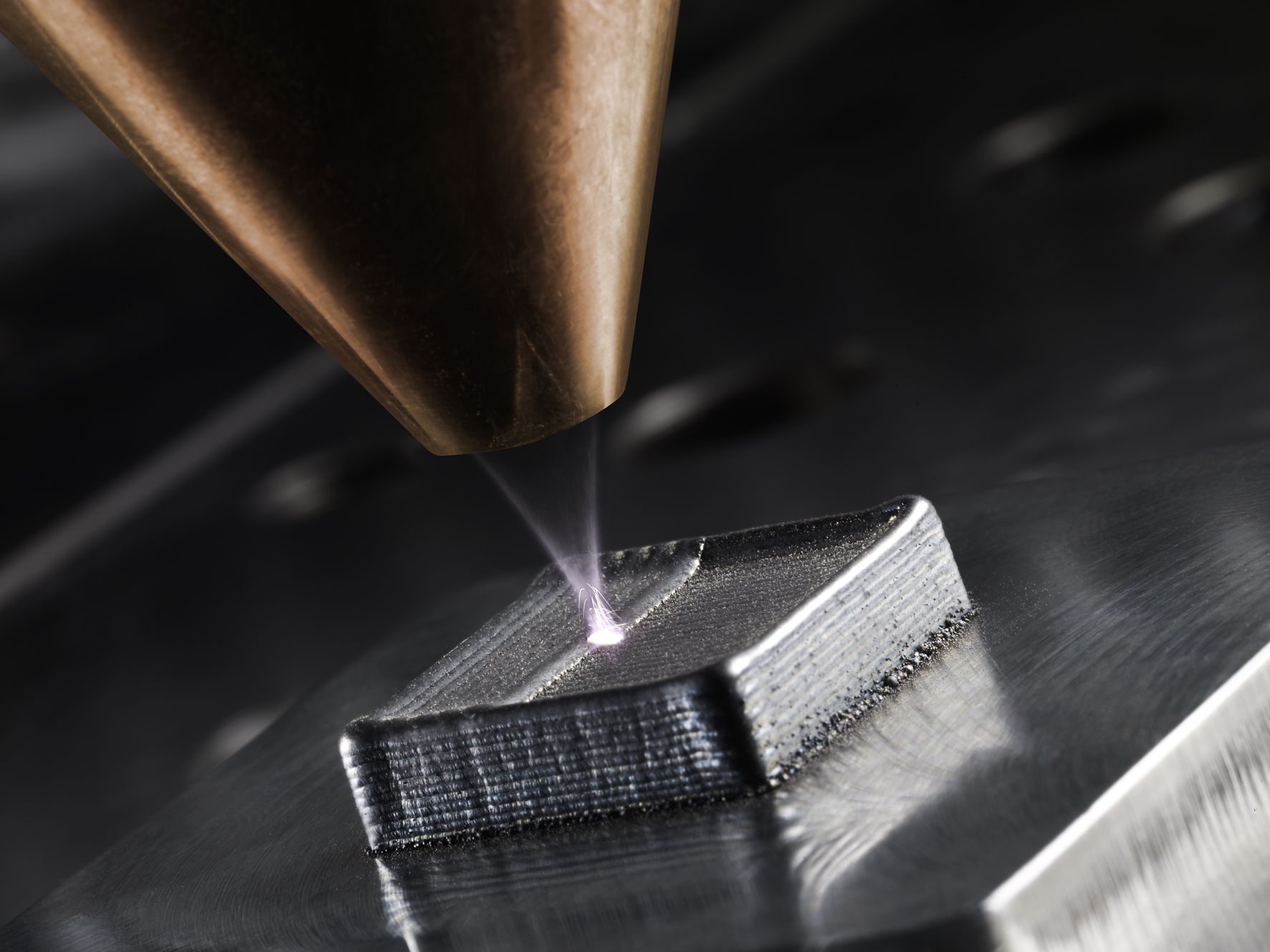

8. Metal

Metal printing is widely used by manufacturers in aerospace and energy industries to create customized metal parts. 3D printers can quickly and efficiently create metal parts that traditional manufacturing cannot.

At the same time, laser sintering of metal promises to change the logistics of these manufacturing industries as much as the designs of the parts themselves.

Because parts can now be made locally near the application site, there is less demand for parts to be shipped in from far off locations around the globe.

9. Polycarbonate

According to Wikipedia: “Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent.”

Though polycarbonates are sometimes difficult to print with, their strength and durability is on par with nylons. They are good options for anyone looking for a material for a high-stress application in a professional application.

10. Conductive

Conductive filaments are often PLAs that are infused with graphene, which is a novel material made of carbon that conducts electricity. When mixed into PLA, the plastic can be used to print electrical circuits and other components of electrical equipment.

Experimental 3D Printing Materials

11. Bio Inks

Biological applications for 3D printing promise to change the way biological research is done. Using Bio inks that contain living cells, bio printers can quickly create cell tissues and even organs for use in research or medicine.

For example, this process is revolutionizing the way cancer research is performed by drastically lowering cost of growing and obtaining tissue cells needed for experiments in laboratory settings.

Bio inks can also be used to create new products for the medical industry, such as living skin grafts for treating burn wounds, which would otherwise have to be taken from another part of the patient’s body.

12. Medical Grade Plastics

3D printers can use medical grade plastics and anti-microbial plastics to create medical devices. The most widely covered way in which 3D printers are changing medical practices is their use in the creation of cheap, customized prosthetics.

3D printers can create prosthetic limbs, teeth, and even support structure for applications inside the body. Customized medical devices can be created on the spot to save lives in emergency situations. And 3d printed hearing aids can fit customer’s ear better so they can use their hearing aids with more comfort.

13. Food

One of the most innovative use of 3D printing is in the food industry. 3D food printers like the Foodini use a pureed food paste to print edible treats. They can create foods like pasta and pizza in a fraction of the time that traditional methods require.

Also, with a heated printer bed, the food can be cooked immediately after it is extruded. Check out the pancakebot, which can make pancakes automatically. You still have to flip them though.

And while 3D food printing is still limited in its ease of use, it holds promise for applications in restaurants as well. Recently a completely 3D printed popup restaurant toured several cities around the world.

The chefs and engineers who ran the restaurant printed all of the furniture, cutlery, and food from scratch in each location. You can read more about it here.

Overall, 3D food printing is still very new, but someday 3D food printers might be a common kitchen appliance.

14. Ceramics

Ceramics are one of the most recent additions to the list of materials that are printable. Ceramic 3D printers can create beautiful ceramic objects out of extruded ceramic paste.

3D printed ceramic objects can be fired in an oven just like any other ceramic object, and can take glazes and sealants. Ceramic materials in 3D printing hold a lot of promise for applications both in printing dishware or decorative objects and also in manufacturing ceramic parts for machines in various industries.

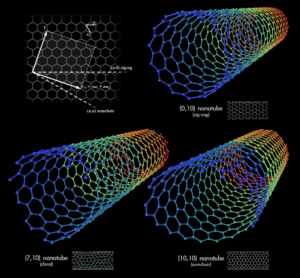

15. Nano Inks

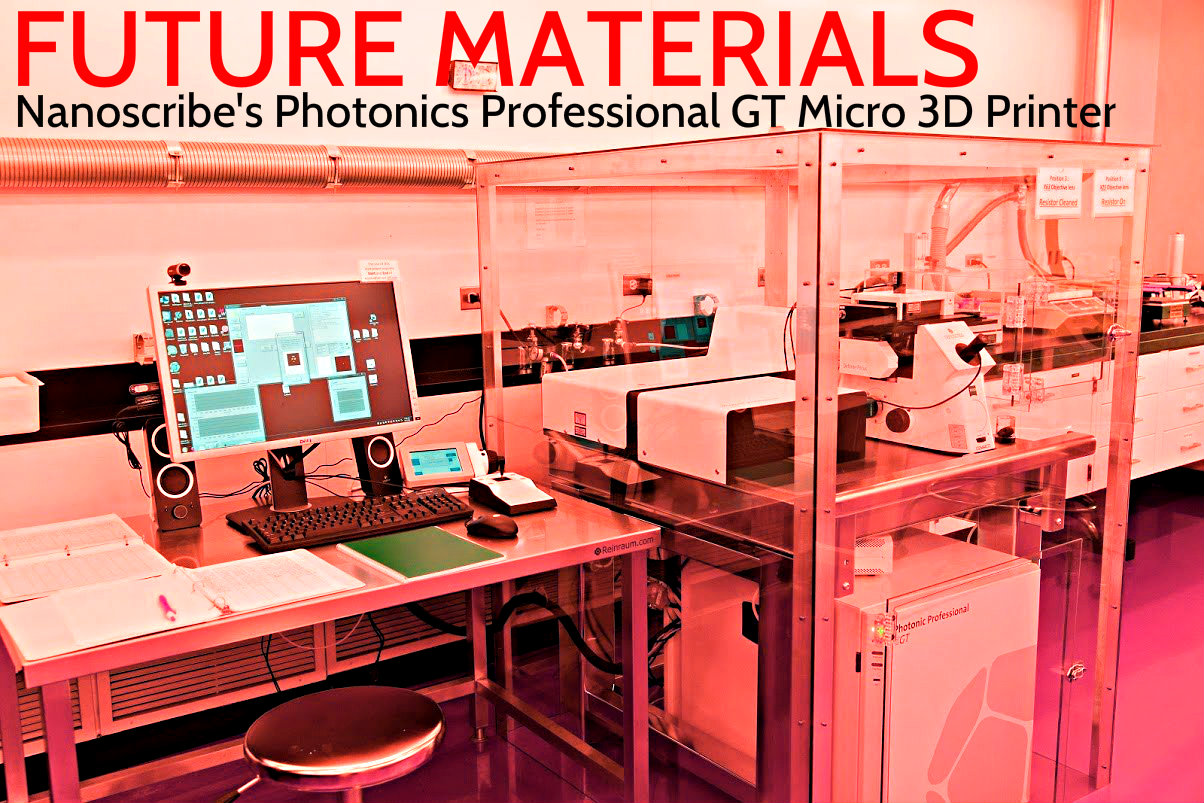

3D printing of nanoparticles could quickly revolutionize the way electronics, photonics and other nanotech industries manufacture products. 3D printers that use nanotechnology-based conductive and dielectric inks can print multilayered circuit boards.

3D printing of nanoparticles could quickly revolutionize the way electronics, photonics and other nanotech industries manufacture products. 3D printers that use nanotechnology-based conductive and dielectric inks can print multilayered circuit boards.

3D printers using specialized photoresists can print products for the photonics industry. Nano-scale 3D printers can be used to create structures that are as small as a few nanometers in size, which can be applied to robotics, bio-sensors, nano filters and novel drug delivery systems for medications.

Conclusion: 3D Printer Filament Comparison Guide

The 3D Printer Filament Comparison Guide above is not exhaustive but it is a good idea. Many new materials are on the horizon and being developed at the moment.

Some of the most interesting applications are in nanotechnology and biotechnology industries.

But the current pace of innovation isn’t limited to high tech industrial printers alone. Consumer 3D printing is changing quickly as well.

For instance, the prices of metal printers are dropping quickly and may soon become available at the consumer level.

That will open up a completely new area of consumer applications for 3D printing. And as the 3D printing industry expands, new materials will be needed to meet demand for novel applications.

These are exciting times, and we can’t wait to see what comes next.