Antimicrobial filaments solve one of the major problems with regular filaments like PLA, ABS, and PETG: they can’t be completely sterilized. That means that most filaments are not useful for medical applications. Even printing kitchen items is an iffy prospect.

The problem is this: as thermoplastics cool and harden, microscopic holes and cracks form on the surface. These tiny nooks and crannies are perfect hiding spots for germs and allergens. Cleaning agents can’t get into these holes because of surface tension: on a microscopic level, surface tension acts as a barrier that prevents liquids from flowing freely into tiny openings.

Can you sterilize 3D printed objects by heating them?

Yes! The only way to truly sterilize a 3D printed object is to heat it up. But, of course, if you heat a thermoplastic too much, it deforms and loses its shape. That being said, you can heat regular filaments up to high enough temperatures to sterilize them without melting them, at least a few times.

For instance, PLA has a melt temperature of 190 degrees Celcius, but you only need to heat an object up to 121 degrees Celcius (250 F) to sterilize it (this is the temperature that autoclaves in science labs use to sterilize lab equipment). There might be some minor deformations of the shape, but probably not. The problem is that many plastics become brittle after heating them up a few times, so you might only be able to get a few uses out of them before they fall apart.

(Note: you need to heat objects up to 121 degrees C and keep them that hot for at least 20 minutes to properly sterilize them, because, believe it or not, some pathogens can survive at that temperature for a while.)

The Food and Drug Administration (FDA) has so far remained somewhat aloof on the topic, but they have approved specific filaments here and there. However, many authoritative voices across disciplines and institutions have recommended avoiding using 3D printed objects in the kitchen. They are not technically “food safe” because of the difficulty of sterilizing those little nooks and crannies where germs can hide. The same is true for children’s toys: technically, 3D printed objects harbor germs that could pose health risks for kids.

That has not stopped people from giving their toddlers 3D printed toys or making 3D printed cups and bowls, though. Will these objects make you ill if you eat out of them? Probably not. After all, you can clean them with soap or some other disinfectant and remove the vast majority of pathogens from their surfaces. But those little holes are harder to get to with traditional cleaning agents, so exercise caution.

Scientists who use 3D printers in laboratories run into this problem of sterilization sometimes. After all, scientists use highly specialized objects, sometimes only once and for one specific application. So it is handy to be able to quickly print out these designs in the lab on the fly as the need arises. For experiments that demand sterilization, for instance in microbiology labs and medical labs, objects made out of regular thermoplastic filaments can often be used if they can be autoclaved.

Food Safe Coatings

One alternative to antimicrobial filaments that is worth considering is applying a coating to finished prints that is food safe. The FDA has approved the use of certain polymeric coatings, but use these at your own risk.

The idea here is to encapsulate 3D printed objects in a coating that is food safe so that you don’t have to worry about the nooks that printed objects have. These coatings are widely used, so search around on forums for more information.

Antimicrobial Filaments Sterilize Themselves

That’s where antimicrobial filaments come in. These filaments have additives that are naturally toxic to microbes (but not to humans). For example, copper is naturally toxic to microbes, and filaments that contain copper will make those microscopic nooks and crannies inhospitable places for germs and other pathogens to hide in.

Does that mean that you can use any copper filament? No. You need to make sure you pick up specifically designed antimicrobial copper filaments that have the necessary proportion of copper fill added to them, and the copper additive has to be the right type of copper and the particles have to be the correct size. After all, copper fill particles that are relatively large could leave gaps between them where germs can hide in the plastic substrate. Think of it as the difference between boulders and sand: it’s easier to hide between two boulders than between two grains of sand.

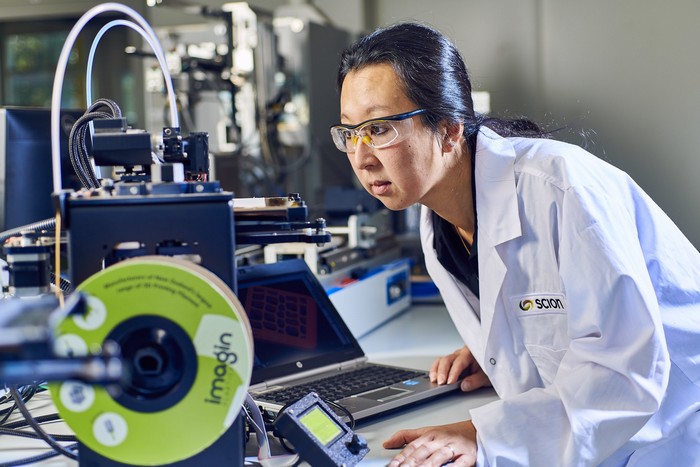

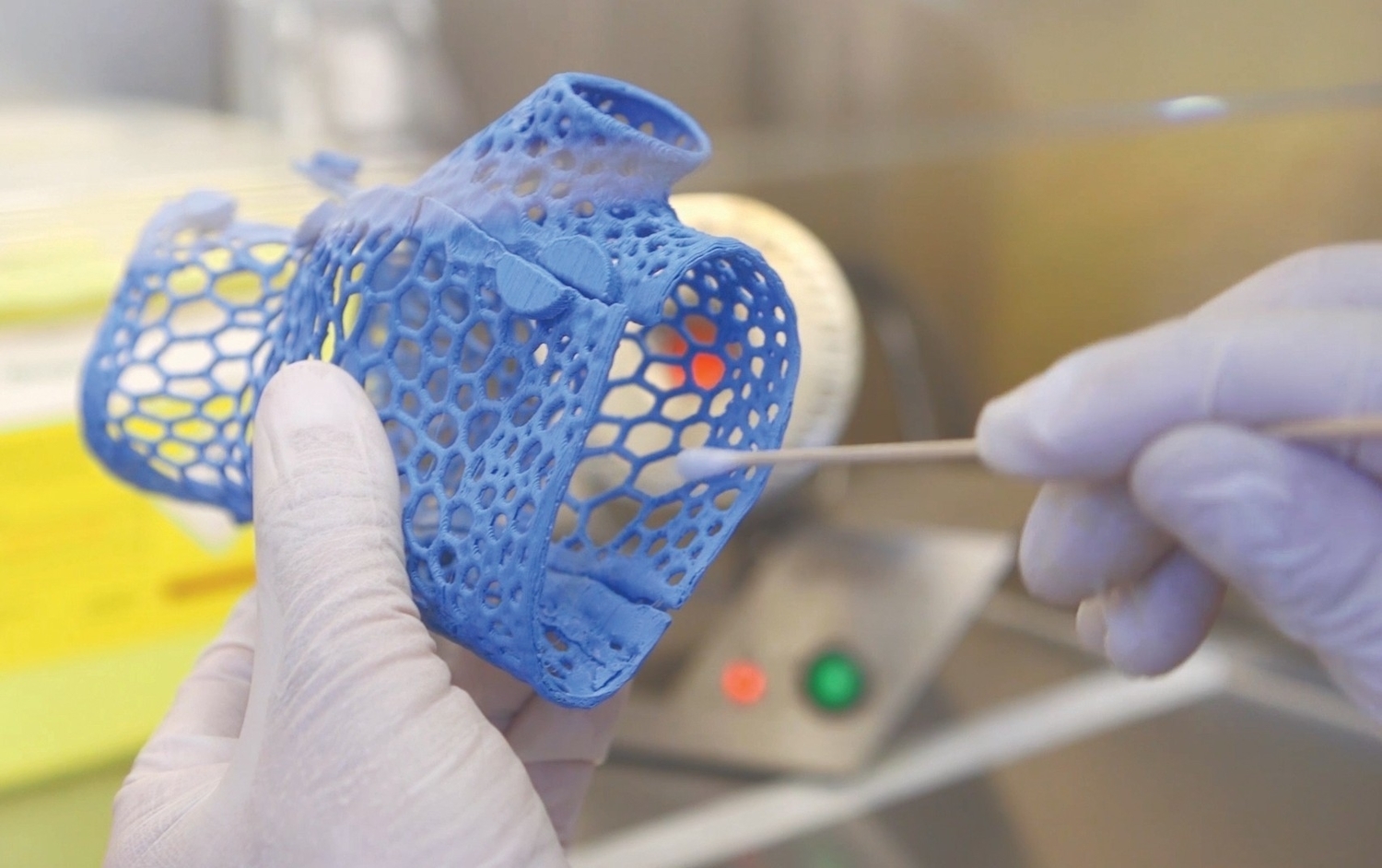

That’s why antimicrobial filament manufacturers like Copper3D use a patented nano-copper additive. Their filaments are FDA approved for use in medical contexts and other contexts where sterilization is paramount. Check out this screenshot from their website (they call their patented material PLACTIVE):

Copper is not the only additive that gives antibacterial properties to filaments. XYZprinting sells a filament that makes use of a silver additive to achieve a similar result. Silver is also toxic to microbes like bacteria and fungi. By mixing it into their filament, they have been able to produce a filament that can effectively be used in applications that require sterility.

XYZprinting has a mixed reputation as a company, and this filament is not FDA approved, so use it with caution. But it is an option worth checking out, especially when other microbial filaments are out of stock.

Antimicrobial filaments vs. Antibacterial filaments

You may have noticed that copper3D filament is called “antimicrobial” filament, whereas Xyzprinting filament is called “antibacterial” filament. These terms are often used interchangeably, which is confusing. But it is an important distinction and it’s worth understanding the difference before making a purchase.

Antimicrobial filaments are toxic to a wide range of organisms including fungi, viruses, bacteria, and protozoans. These are all different types of microscopic critters that can cause illnesses, so if you want the most protection from a filament, go with filaments that specifically list themselves as having “antimicrobial” properties.

Antibacterial filaments, on the other hand, are specifically designed to repel and destroy bacteria. Bacteria are everywhere and on almost every surface. Very few objects have no bacteria on them. The benefit of these antimicrobial filaments is that they can keep bacteria that would usually contaminate objects clean and free from bacteria specifically.

That hasn’t stopped filament companies from using these terms inaccurately, however. Even Copper3D, which has secured FDA approval misuses the term antibacterial on their website:

Woops!

Does this matter that much? Generally speaking: no, not really. And again, these terms are used interchangeably in a range of medical and research contexts. But if you are looking for filaments for specific applications that require different types of sterilization, it could matter.

Best Antimicrobial And Antibacterial Filaments

1. Copper3D Antimicrobial PLACTIVE Filament – FDA Approved

PLACTIVE by Coppper3D is a best-in-class cutting edge antimicrobial PLA available on the market today. Crucially, it is one of the only antimicrobial PLAs with FDA approval that is available to consumers. Considering how hard it is for products to achieve FDA approval, that is a huge vote of confidence.

Because it has FDA approval, it can be used to print medical and kitchen equipment. Researchers can use it in labs and hobbyists can use it to print toys for children without worrying that micro-tears in the plastic will harbor germs.

From the website:

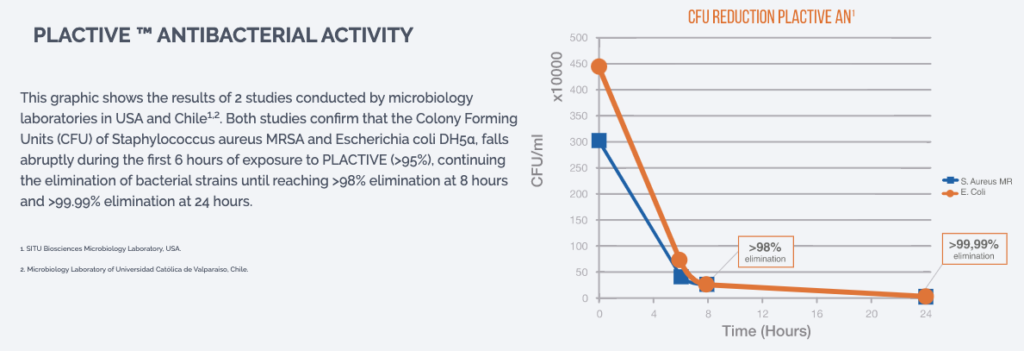

“Antibacterial properties confirmed by two microbiology laboratories in Chile and USA. PLACTIVE™ is a FDA Registered Material and EU compliant (No. 10/2011, No. 1935/2004 and No. 2023/2006). The manufacturer also has certification ISO 9001/2015 and is REACH compliant.”

Key features:

- FDA approved

- REACH compliant

- 95% sterilization after 6 hours

- 98% sterilization after 8 hours

- 99% sterilization after 24 hours

- Prints just like regular PLA

- It really does sterilize itself

Currently being tested by NASA for space missions

Not only are Copper3D filaments FDA approved and REACH compliant, they are also trusted by other US government agencies like NASA. Due to the fact that bacteria cover almost every terrestrial surface on Earth, one major concern for space missions is sterilization so that microbes are not introduced into extraplanetary environments. After all, it would be disappointing to “discover life on Mars” only to realize that the microbes found on the surface originated on Earth! PLACTIVE takes care of this problem.

As an advanced research material, the fact that it is available to consumers is special. It behaves just like regular PLA so you don’t need any special equipment to use it. You may want to upgrade your 3D printer nozzle to be able to handle extra abrasive filaments as a precaution before using it. But in general, it is a plug-and-play filament.

PLACTIVE is also clinically approved for medical contexts, so it can be used to make prosthetics for amputees. It is perfect for use with surgical equipment as well because it will not contaminate sterilized tools.

Pros

- Protects against more than 99.99% of fungi, viruses, bacteria and a wide range of microorganisms

- FDA approved

- REACH compliant

- Behaves like regular PLA

- Clinically tested and approved for medical applications

- NASA is currently testing it for use in space missions

Cons

- More expensive than some brands

- Limited availability

PLACTIVE is an ideal antimicrobial 3D printer filament and the best antimicrobial filament available on the market today. There is no other filament out there that comes close to the quality standards set by the antimicrobial PLA.

Note that it is antimicrobial, which includes antibacterial, and it sterilizes fungi, viruses, and other microorganisms as well. Other filaments do not offer this level of performance.

1. Purement Antimicrobial PLA

Purement PLA is made by the Korean manufacturer BNK chemicals. They claim that their filament is the first antimicrobial ever made, which is the sort of thing a marketing department would say. We recommend being very cautious with this filament and asking the company for documents confirming their claims.

Also, make sure to get information from Purement about what chemical additive they have put into the filament to make it antimicrobial. Sometimes these antimicrobial agents can be toxic to ingest, so in those cases, the filament would not be useful for making toys for kids or kitchen equipment. It could still be useful for prosthetics or scientific applications. It really just depends on what chemical Purement used to give the filament its antimicrobial properties.

Key features:

- Antimicrobial PLA

- Certified by the SIAA

- Registered by FDA (not the same as approved)

- ROHS Tested

Basic Antimicrobial PLA for home printing

Unfortunately, we can no longer find much information about this PLA and we are not sure BNK chemicals is still worth purchasing filament from. This filament caused some media buzz back in 2015 – 2017 but since then the filament industry landscape has evolved, and BNK has not kept up with the times. Their website is no longer functional, and their listings on Amazon are basically inactive.

The one user was able to get their hands on a roll of this filament in early 2019 reported that it is brittle before printing but hard after printing. Therefore, if you use it, make sure to be very careful guiding the filament into the hotend of your printer.

Pros

- Antimicrobial PLA

- Certified by the SIAA

- Registered by FDA (not the same as approved)

- Several colors available

- Prints easily

Cons

- Manufacturer might no longer be in business

- unclear what chemical additive is used to give it antimicrobial properties

- Not FDA approved necessarily – verify with BNK before purchasing

3. Taulman Nylon 680

While Taulman Nylon is not an antimicrobial filament, it is sterilizable using conventional sterilization techniques.

To be clear, 3D printed nylon will still have those pesky microscopic nooks and crannies where germs can hide just like every other thermoplastic used in 3D printing. But the fact that nylon has such a high melt temperature means that you can effectively sterilize nylon objects by heating it up to 121 degrees Celcius or more without remelting the plastic.

What makes nylon different from PLA and ABS is that you can sterilize them in an oven many times over and over without degrading the material. PLA, PETG, and ABS will most likely degrade after just a few heatings. These Thermoplastics can become brittle and deform after heat treatment even if they do not melt. Nylon does not have this drawback.

Key features:

- Ultrahigh-strength

- Works with most desktop 3D Printers

- Suitable for biomedical and dental research

- Sterilizable using heat sterilization, will not degrade

- Food and dishwasher safe

Can be sterilized in an oven or pressure cooker

To sterilize nylon, you can simply place objects on a baking sheet in the oven in your kitchen and bake them for at least 20 minutes at 121 degrees C (250 degrees F). Make sure to bake them for at least 20 minutes because some microbes can survive if objects heat up unevenly due to their design or any insulating effects of microscopic dirt particles.

Another way to sterilize Nylon is to place objects into a pressure cooker, such as an Instapot. Pressure cookers heat objects by building up steam pressure inside of a sealed chamber. The dual effects of the heat and intense pressure (which can reach levels several atmouspheres in strength) will kill every microbe that could be contaminating the object.

Pros

- Food safe and dishwasher safe

- Super strong compared to antimicrobial PLAs

- Suitable for biomedical research and dental implants

- Works with most FDM printers

Cons

- May require upgraded nozzles due to abrasion

- Not antimicrobial (but easy to sterilize)

- Can be challenging to print with depending on skill level

Conclusion: Best Antimicrobial 3D Printer Filaments

The range of antimicrobial 3D filaments is expanding as 3D printers find applications in biomedical and scientific research, but the options are still relatively limited. Copper3D is the clear market leader at the moment but there is a lot of room for competition.

What makes Copper3D so good is that it is designed specifically for research applications but it is available to the general public. NASA is currently testing it in their projects, and regulatory agencies such as the FDA and other international agencies have already approved its use in food and medical applications.

The main problem with Copper3D is that it is not always available because of how popular and specialized it is. So in applications where sterilization is of the utmost importance, you might want to explore nylons from Taulman that can be sterilized in conventional ovens and pressure cookers. They are more available and their performance properties are superior to PLAs in many ways, though nylons are a bit harder to print with.

Until just a few years ago, Purement was a market leader in this space, but it not clear that its manufacturer, the Korean company BNK is still active. We will continue to monitor this situation.

In general, it is always a good idea to ask companies for documents proving that the FDA did in fact approve their products. Sometimes the FDA will approve a material in general based on the assumption that it will be used at industrial scales. But what makes 3D filaments vulnerable to germs is the way they are printed, not the material itself. So if the FDA hasn’t approved a filament for use specifically with FDM printers, it’s best to avoid using and just go with a Nylon or regular PLA that can be sterilized in an oven.

And that’s the thing: regular PLAs and ABS and PETG can technically be heat-treated, but they will degrade over time. That’s why it’s best to use nylons, which can be heated as many times as you like without losing its material characteristics.

We hope this guide answered your questions. This is a complicated topic, so make sure verify all information yourself, and use these materials at your own risk. Check the FDA’s website for information to confirm all claims made about filaments and materials before using them, and exercise caution when information is not available.

If we missed anything or new filaments have become available since this article was published, please feel free to leave comments and questions in the comments section. We will continue to update this article as the industry evolves. As always, happy printing!

Interesting article, but though Taulman nylon 680 is FDA approved. Tualmans Spec sheet says its not FDA approved for medical use. Taulman doesn’t even recommend it for Medical use. Take a look at the spec sheet here:

https://taulman3d.com/nylon-680-spec.html