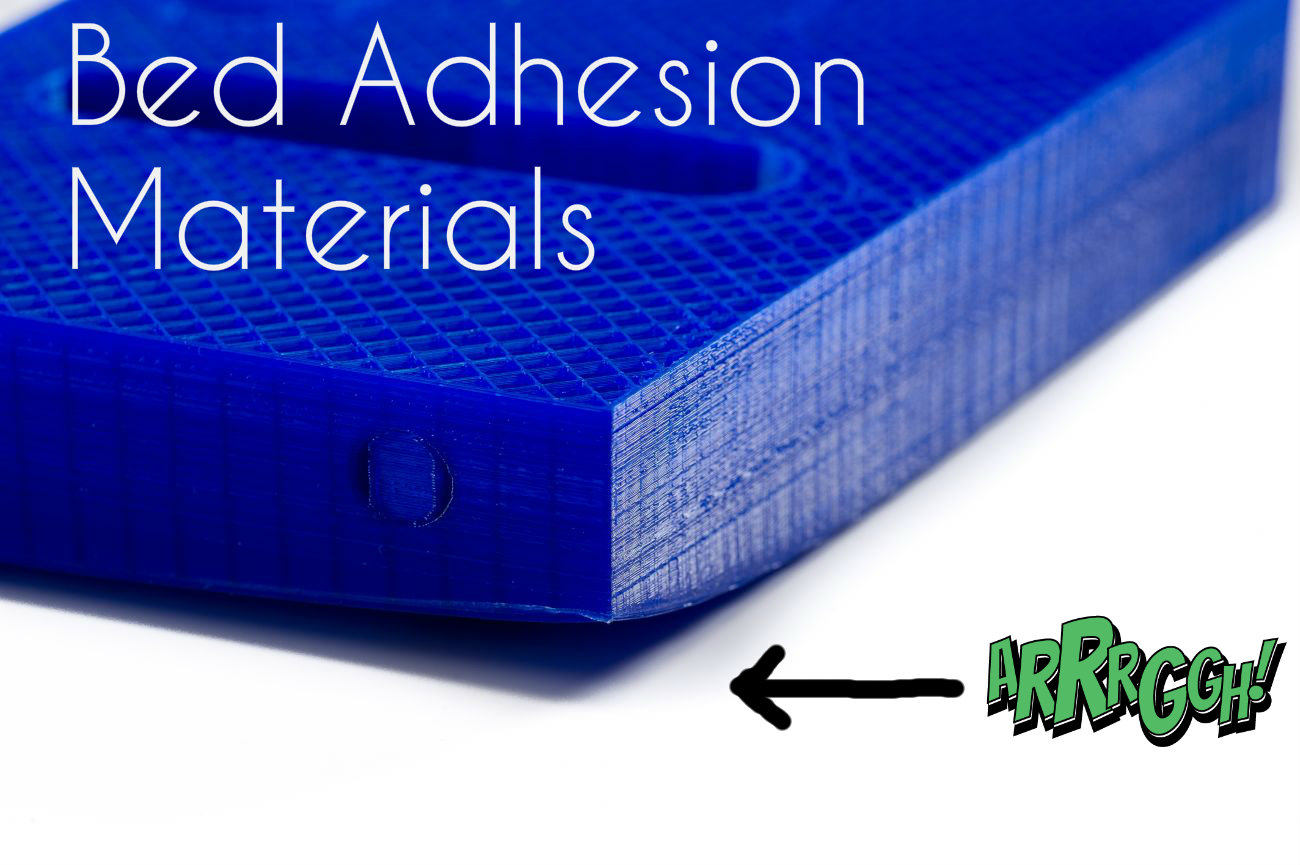

For successful 3D printing, it is important to have the best 3D printer bed adhesion surface. Nothing is more disappointing and frustrating than seeing your creation come alive only to have it break apart, warp and end up looking like something straight from a 1 year old’s imagination!

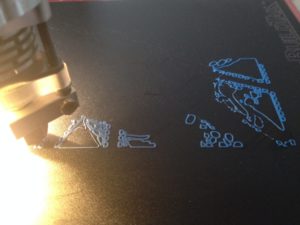

It has been said that the first layer of your 3D printer is the most important to ensure your design comes out correctly. Now, nothing will ruin that special moment more than bad adhesion.

PLA won’t stick to painters tape? Check out Gizmo Dorks PEI Sheet now.

It’s the quickest solution:

- Reusable for many prints

- Works with heated and unheated beds

- 0.8mm thin so it won’t take up any print height

There are tons of ways to solve bed adhesion problems, but some are better than others. We have the best solutions right here: check out our list of the best 3D printer bed adhesion surfaces below!

Also, check out our complete list of 3D printing accessories.

Best 3D Printer Bed Surface: Excellent Adhesion

Gizmo Dorks PEI Sheet 10″ x 10″

Product Overview

Out of all of the dorks out there who are looking for the perfect 3D print, Gizmo Dorks are the most persistant. Gizmo Dorks PEI Sheet will remove any adhesion frustration from occurring during the masterful creation of your project.

Gizmo Dorks PEI(Polyetherimide) sheets allow for both ABS and PLA printing directly onto the print surface without the need for added adhesives – tapes, sprays, etc.

Gizmo Dorks PEI(Polyetherimide) sheets allow for both ABS and PLA printing directly onto the print surface without the need for added adhesives – tapes, sprays, etc.

Each single sheet, roughly 0.8mm, installs directly on top of your build platform and you can reuse it for multiple prints.

Features and Benefits

- You can reuse it for many prints

- It works with both heated and unheated beds

- 0.8mm thin so it won’t take up any print height

- No need to used other adhesives

- You can cut it to fit the size you need.

Detailed Review

Your 3D design will adhere to the polyetherimide surface on a heated bed and, once it cools off, your design will release. Now, if you are using an unheated PLA printer, your design will adhere as well.

Your 3D design will adhere to the polyetherimide surface on a heated bed and, once it cools off, your design will release. Now, if you are using an unheated PLA printer, your design will adhere as well.

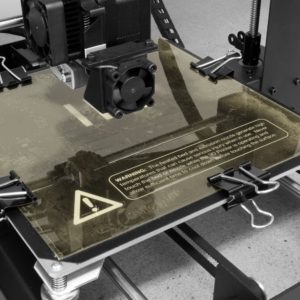

To apply, cut the sheet to size, remove the blue protective film, and stick the PEI to the print bed. Remember to re-level your print bed before printing and you are set to go.

With a super-thin sheet and sticky 3mm double-sided transfer tape, this adhesive sheet is perfect for your 3D printing needs. Make sure that all air bubbles are removed.

When your masterpiece is finished, simply wipe it down with isopropyl alcohol to ensure the best result from your 3D print design.

TIP: For a better life-span for each individual PEI sheet, sand down with 2400 grit paper.

Gizmo Dorks Polyester Film PET Tape

Product Overview

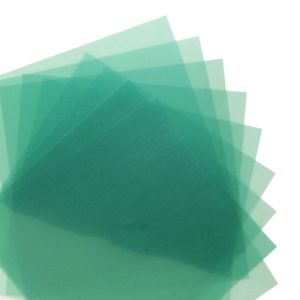

Another masterful creation from Gizmo Dorks is this PET tape for 3D printers. At 10 sheets per pack, this 5-star adhesion sheet will lay to rest your 3D printing worries.

The specs of each sheet are 1 millimeter thick with a 1-millimeter thick adhesive layer, so you won’t lose any height for your prints. Also each sheet is 9″ x 12″ which gives you a lot of space to cut it to the size and shape you need.

The specs of each sheet are 1 millimeter thick with a 1-millimeter thick adhesive layer, so you won’t lose any height for your prints. Also each sheet is 9″ x 12″ which gives you a lot of space to cut it to the size and shape you need.

Most importantly, Gizmo Dorks Polyester Film PET Tape works with both PLA and ABS. That means you don’t have to change it for different materials.

Features And Benefits

- 10 Sheets in each pack

- You can cut the 9″ x 12″ sheets to any size you need

- Works with both ABS and PLA

- More durable the Kapton tape

- Leaves no residue on the build plate when removed

Detailed Review

The Polyester film is perfect for 3D beds that heat up drastically due to the plastic being used. ABS filament, which requires a heated platform, is a perfect match for the Gizmo PET Tape, allowing for the proper adhesion of every 3D creation.

The PET tape is green and more durable than Kapton tape, which at times results in wear and tear. This tape’s max upper temperature is 220 C and leaves no residue when removed.

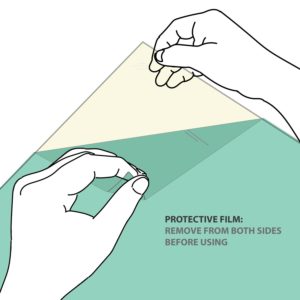

Now, onto the application process! There are two forms of application, dry and wet.

Which will you choose?

Application Process

Dry Application:

Dry Application:

With this method, make sure to use a ruler or credit card to slowly peel and apply the tape to keep it free from bubbles between the 3D print bed and the tape. Tightly press the PET tape with your ruler or credit card while peeling off the protective liner.

Wet Application:

This method is like the dry application, only you are spraying soapy water underneath the PET tape. Remove all liquid with a straight flat edge such as a ruler or squeegee, which will also remove the bubbles.

With this method, you can adjust the PET film seconds after applying it on the flatbed because of the slightly wet tape.

3DMakerWOrld Kapton Tape With Release Liner

Product Overview

The predecessor to PET tape is the infamous, Kapton Tape. Although certain Kapton Tape makers have received some bad rep with slight tares of their sheets, 3DMakerWorld has solved that problem by supplying a phenomenal adhesive tape sheet that allows for any 3D creation to stick.

At the size of 6″ x 6″, this Polyimide tape sheet has a release liner for easy release and installation. It also allows for 3D printing at temperatures as high as 280C.

According to 3DMakerWorld this Kapton Tape allows for excellent bed adhesion for ABS, PLA, PVA, and Polycarbonate 3D printing.

Features and Benefits

- More durable than other Kapton tapes

- Release liner for easy release and installation

- Provides excellent bed adhesion for ABS, PLA, PVA, and Polycarbonate

- Extremely sticky surface

Detailed Review

To prove the quality of the product, customers have mentioned numerous times that it is extremely sticky. Therefore, it is best to spray it with soapy water or Windex before adhering it to your 3D bed.

That will allow you to adjust the position of the sheet as you apply it.

Once you have sprayed it, begin to slowly apply it to your 3D bed and flatten it with a flat-edged object such as a ruler or credit card to remove all bubbles. The process is similar to putting a new screen protector on your smart phone.

Then, enjoy your 3D creation!

WolfBite Premium Heatbed Adhesion

Product Overview

When it comes to wonderful creations that make us proud to be creators, this is one of them. In collaboration with Professor Miodrag Micic, Ph.D., Airwolf 3D brings us a solution to our first-layer 3D printing problems: super strength 3d printer bed surface adhesion!

This premium glass bed adhesion solution is engineered to bond printed parts directly to glass 3D printing build plates without lifting, which is also known as “warpage”. This adhesive solution allows for each item to stick perfectly and release easily after printing is over.

Features and Benefits

- Built specifically with glass printer beds in mind!

- Prevents warping due to uneven cooling

- Each bottle lasts for up to 200 prints

- Use with a Polyurethane foam brush, such as this one.

Detailed Review

Serving as a compliment to either a heated or room-temperature bed, apply a light application to the area of printing. You can begin your creation slowly after and use the same application for multiple 3D designs.

Don’t forget to apply with a Polyurethane foam brush. Here is a link for you to find the exact kind of brush that you need for this stuff.

The best part of WolBite is that every bottle allows for up to 200 3D prints! You won’t run out for a long time.

NOTE: There are numerous versions of each WolfBite Premium Heatbed Adhesion depending on the type of material you will be printing with. Make sure you get the right one for best results. Check them out below!

- WolfBite Nano Premium Heatbed Adhesion Solution for PLA

- WolfBite NITRO Premium Heatbed Adhesion Solution For Nylon

- WolfBite Premium Heatbed Adhesion Solution For ABS

BuildTak 3D Printing Build Surface

Product Overview

Known to be one of the top brands in 3D printing, BuildTak has created a solution for proper 3d printer bed surface adhesion of your 3D design and safe removal. BuildTak 3D-printing build surface is an 8” x 8” square sheet that sticks to any printer bed to enhance the adhesion power of the first printed layer.

No more warping of your designs and no more worries for you.

Features and Benefits

Features and Benefits

- Build sheets adheres to any print bed to help the first layer of filament stick during printing

- Compatible with ABS, PLA, HIPS, PET+, brick, wood, and flexible (TPE) filaments

- Allows for multiple uses of the same sheet

- Heat resistant and durable

- Creates an optimal bond between the build surface and the 3D printed object

Detailed Review

Serving as a compliment to ABS, PLA, HIPS, PET+, brick, wood, and flexible(TPE) filaments, BuildTak offers a highly praised product that ensures proper creation of your design.

One of the bonuses in using BuildTak is that the durable construction of each sheet allows for multiple uses with either the same or different filament material, without having to change the sheet.

You can also use the build surface with t-glase and nylon after applying a thin layer of any washable glue stick onto the surface.

BuildTak sheets also install much faster and with fewer bubbles than tape or films, allowing for minimal effort and ease of mind. With BuildTak you know your creation is safe.

Check out the hundreds of reviews on Amazon from customers saying “perfect build surface”, “first layer always sticks”, and “sticks perfectly”. There is a reason BuildTak is known as one of the best makers of a proper 3D adhesion build surface.

Final Word: 3D Printer Bed Surface

Whether you are a novice in the 3D printing game or you are an expert creator of computer models for an architecture firm, the first layer of your 3D printer is the most important.

With the best 3D printer surface, your first layer will stick with ease, allowing for your masterful creation to come to life layer by layer.

Also, check out our complete list of 3D printing accessories.

Now, proceed, you modern day Da Vinci!