Now that we’ve told you about some of the best wood filaments available, let’s go over how to print with wood filaments.

Wood filament is often difficult to print with. Many beginners buy a roll of wood filament expecting to print with it just like any other PLA filament.

But that is a mistake. Wood filament often requires a fair amount of patience and advanced printing skills to print use.

So here are 5 tips to help you get started for printing with wood filaments.

5 Tips For Beginners About How To Print With Wood Filaments

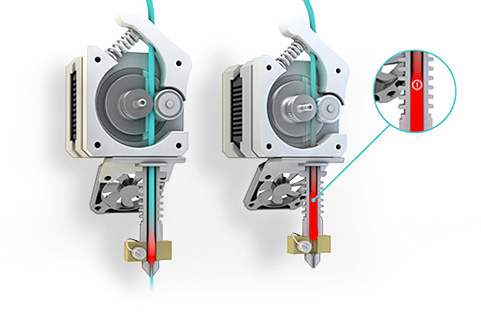

1. Use A Larger Nozzle

First, many wood filaments will feel and look like medium density fiberboard. You might even see huge dark specks in the filament depending on the brand you are using.

That is all normal. However, you should use a larger nozzle with wood filaments so that those large specs don’t jam up inside your nozzle.

We recommend using at least a 0.3 mm nozzle, but the larger the better. In the nozzle pack above, you will get a few different sizes of nozzles, ranging up to .6 mm in diameter.

Using a .6 mm nozzle might seem a bit unnecessary, but it that larger nozzles are less likely to clog in the long run.

Using a .6 mm nozzle might seem a bit unnecessary, but it that larger nozzles are less likely to clog in the long run.

And if you don’t like the look of the layers when you use a larger nozzle, you’re not alone. Just remember that you can always sand the layers away after the print is finished if you don’t like the look of the larger layering.

Clogging a nozzle with wood filament is not a fun experience. If you don’t catch the problem in time and filament burns inside of the extruder, then you will be left with a black, bunt mess to clean up.

2. Always Remove The Filament From The Hotend When Not Printing

Next, if you are going to turn off your printer or interrupt printing for any reason, always always ALWAYS remove the filament from the printer head.

Otherwise the wood particles in the filament will burn up and create a black sticky mess inside your printer head. If that happens, you will have to clean out the extruder with a cleaning filament.

eSUN sells a really good cleaning filament for cheap, so if you need it, pick up a roll. Cleaning filament will save you so much time that would otherwise be spent unclogging your extruder.

eSUN sells a really good cleaning filament for cheap, so if you need it, pick up a roll. Cleaning filament will save you so much time that would otherwise be spent unclogging your extruder.

Cleaning filament will also remove a surprising amount of gunk from the inside of your printer. After you run it through your printer once, you will realize how beneficial it is.

3. Keep The Temperature As Low As Possible

If you are just learning how to use wood filaments, you might be excited by the idea that you can print darker burned wood finishes on your wood pieces by increasing the temperature.

If you are just learning how to use wood filaments, you might be excited by the idea that you can print darker burned wood finishes on your wood pieces by increasing the temperature.

The problem is that many wood filaments are very sensitive to higher temperatures, so one degree off and you could be in for a bad time. If the fine wood particles ignite in your hotend, you will get a nasty clog.

As a result many people who use wood filaments don’t even bother trying to find that sweet spot where the melt temperature causes a darker wood finish. Instead, see if you can find a wood stain that will achieve the same or similar effect.

There are many wood stains available that might save you hours of frustration trying to find those magical few degrees.

4. Use High Layer Heights And Faster Printing Speeds

Using a high layer height and relatively fast print speed will keep the filament moving through the hot-end quickly, giving it less time to burn. Sure, higher layer heights don’t look as good, but you can sand them away after the print is finished.

Faster print speeds will also limit your ability to give your prints a darker shade of wood color or stylistic burn marks, as is displayed in the groot figure above.

But with a lighter or other flame, you can give the print some darker burn colors during post processing after the print is complete.

But with a lighter or other flame, you can give the print some darker burn colors during post processing after the print is complete.

Also the faster print speeds may increase the likelihood of z-wobble, so make sure your printer is super stable beforehand. This won’t be a problem for the higher end printers, but if you bough a kit or a cheaper Prusia clone, just make sure the frame is tight and sturdy.

5. Use Higher Retraction

Wood filaments tend to be a bit more runny than regular PLA filaments. This means that while your printer head is moving into position, retraction settings for normal PLA might not be able to keep wood filaments from leaking out of the nozzle.

Normally, if nothing stops it, the liquefied plastic will ooze out of the printer nozzle due to the pull of gravity when it is not being actively extruded, such as between layers. This is often what causes stringing, for instance.

The best way to stop filament from oozing out of the nozzle is by using retraction, which is when the hotend moves upward away from the printer bed.

The best way to stop filament from oozing out of the nozzle is by using retraction, which is when the hotend moves upward away from the printer bed.

This movement introduces an upward force, which momentarily pushes the filament up, preventing it from coming out of the nozzle due to the pull of gravity.

Using retraction heights that are too low could cause a huge stringy mess and turn your wooden cowboy figurine into a tangle of tumbleweed. So as a precautionary measure, it’s a good idea to increase your retractions speeds and distances a bit.

Wrapping It Up: How To Print With Wood Filament

Hopefully this article helped you get some idea of what to expect when printing with wood filaments. If you have any other suggestions for how to avoid clogs or get the perfect finish from you wood prints, leave them in the comments below.

Hopefully this article helped you get some idea of what to expect when printing with wood filaments. If you have any other suggestions for how to avoid clogs or get the perfect finish from you wood prints, leave them in the comments below.

And remember, if you are looking for the perfect wood filament to try first, check out our article about the best wood filament brands. There are a few unusual types of wood filament discussed in that article that you might not know about.