3D Printing is complicated and the terminology can often be technical and obscure. Here you will find a list of some of the most common terms in 3D printing and a full explanation of their meaning.

Below are some common terms in 3D printing. Check out a complete glossary of 3D printing terms here.

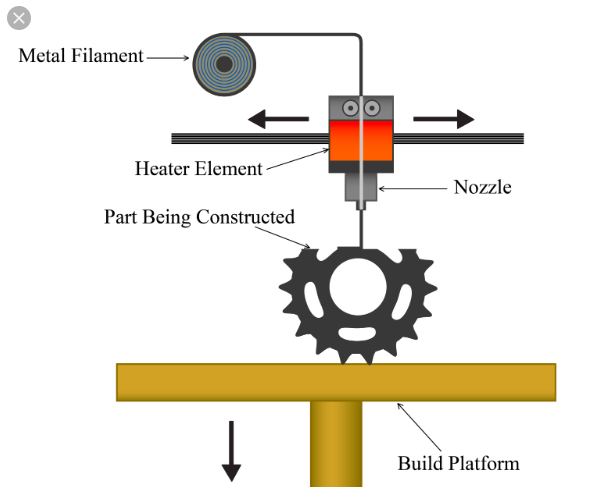

1. FDM vs FFF

You might have noticed that we used two different terms to refer to 3d printers, fused filament fabrication (FFF) and fused deposition modeling (FFF).

The key is this: FFF and FDM both refer to the same type of 3d printer.

But Stratasys inc., one of the largest 3d printer companies in the world, holds a trademark on the term fused deposition modeling and it’s an abbreviation, FDM. As a result, FFF has become the standard alternative term used to talk about these types of 3d printers in the popular media.

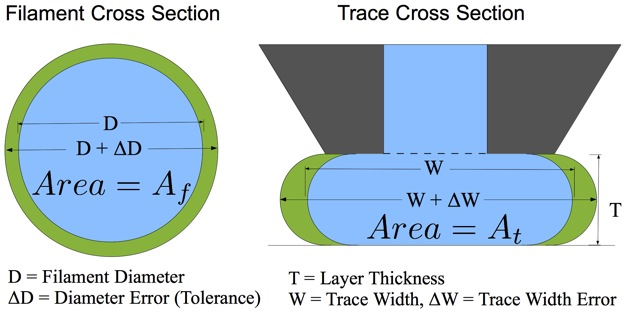

2. Tolerance

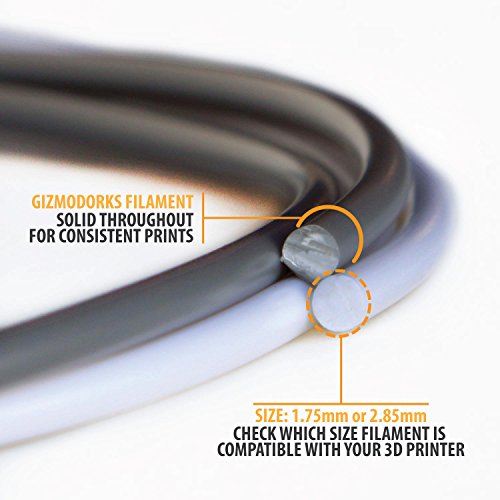

Tolerance is a measure of the small changes in diameter across the length of a piece of filament. It is measured with a micrometer and is probably the most important factor to consider when buying filament.

Filament comes in two diameters: 1.75 mm and 3.00 mm.

But depending on the quality control standards of the manufacture, those diameters can vary ever so slightly across many meters of filament. So one way to characterize tolerance is that it is the error range in the diameter of the filament. This error is measured in 1/100 of a millimeter.

Since 3d printing requires such a precise amount of filament to flow through the extruder for it to work, even these minute changes can have big impacts on the success of a print.

Tolerance is usually expressed as a range, and the industry standard tolerance range for filament is +/- 0.05 mm. This means that the diameter of a filament should not vary from the median diameter by more than 0.05 millimeters across the entire length of the spool.

So a filament with a stated diameter of 1.75 mm should stay between 1.70 and 1.80 mm, for example.

The reason this matters is that drastic changes in diameter will cause problems for your printer. Extruders depend on an even flow of filament through the hotend and nozzle in order to accurately deposit the right amount of filament layer after layer.

If a significantly larger or smaller amount of filament enters the hotend, the flow will easily be disrupted. This will cause either a build up of filament in the hotend leading to a clog or not enough filament entering the hotend leading to poor layer quality in the printed object.

Many filament brands pride themselves on exceeding the industry standard for tolerance. Hatchbox, for instance, boasts that it’s filaments have +/- 0.01 mm tolerances.

That is an amazing achievement, and several other high-quality filaments like ColorFabb, Faberdashery, Makerbot, and Ultimaker claim similarly fantastic tolerances. It is the most important factor in the quality of filament brand so definitely make sure you check out a brand’s tolerance before you buy it.

3. Layer bonding

Layer bonding is the ability of one layer of extruded plastic to bond with another layer of plastic. If the filament you are printing with has poor layer bonding, then your prints will have cracks or break more easily. This is called delamination.

In severe cases, layers can even come apart during printing. This happens most often when a layer cools faster than the layer on top of it, causing the bottom layer to contract at a different rate than the top layer. While the contraction of the cooling layer can cause warping, it can also pull the cooling layer apart from the layer above it.

Layer adhesion can be improved by optimizing your printer’s settings. For instance, if you do experience delamination as a result of uneven cooling across the print, try using a heated printer bed and a high strength printer bed adhesion material or fans to regulate the cooling of the layers.

You can also try increasing your print speed to reduce the amount of time a layer has to cool down before the next layer is deposited on top. Since the bottom layer is still warm when the top layer is deposited, the two layers can bond more easily and create a stronger bond as well.

According to research by 3D Matter, faster printing speeds increases the overall strength of an object, but only by a small amount. Still, every bit of strength helps especially when printing functional parts that will need to withstand more stress.

4. Surface quality

The quality of the surface of an object depends on several factors: filament quality, filament additives, printer settings, and post-processing. Depending on these variables, printed objects can have very different surface qualities.

Some printed objects have a rough surface, and some are smooth. Some surfaces are glossy while others have a matte finish.

The quality of the filament you buy can really affect the surface quality of objects. You can often tell what the surface of your prints will be like as soon as you unwrap a spool.

Lower quality filaments tend to have rough, uneven surfaces and are simply less pleasing. But high end filaments have amazing, silky smooth surfaces that are super pleasing to the touch.

Many filament brands will put additives into their plastic in order to achieve a more desirable surface finish. This can have negative effects on the ease of printing for those filaments since higher temperatures and more exact settings are often required to deal with the properties of the additives.

But the results are often well worth it, especially for PLA. For instance, check out the Hatchbox Black PLA (Check on Amazon). It has a glossy finish similar to ABS which is likely the result of additives. And it looks great!

Printer settings can also affect the surface quality of a printed part. For instance, layer height will determine how visible each layer of plastic is on the surface of the printed part. Higher layer height will cause the layers to be more visible and the surface rough to the touch while lower layer height can sometimes make layers almost imperceptible.

If all else fails, there are several post-processing techniques that can help improve the quality of an object’s surface. When printing with ABS, consider using an acetone bath to smooth out rough patches bring out the natural gloss of ABS.

You might sacrifice some print detail, but there are ways to avoid that as well. Wood filaments can be sanded and metal filaments can be polished. There are many post processing techniques out there, which we will go into in a future post.

5. Strength, toughness, and rigidity

There are a few ways to measure the strength of a material. In general, strength is measured by a material’s ability to withstand stress. There are various types of strength, such as elongation or elasticity, rigidity, torque or twisting, and impact strength.

Impact strength is probably the most common type of strength that concerns 3D printers since it measures how much a material deforms when force is applied to it. However, a common test that you can do at home is called the bend test. Click here to see how one Ultimaker user performed a bend test in their home.

In general, for high strength filaments, check out PLA+, ABS+, PETG, and Nylon filaments. These filaments are good for use in functional parts such as door handles and light switches – anything that requires the part to withstand significant stress.

6. Clarity and opacity

Opacity is the ability of light to penetrate a material. A material that lets a lot of light pass through it is said to have low opacity. This essentially means it has high clarity. Conversely, an object with high opacity usually doesn’t let any light through, so it is not see through at all.

Transparent filaments have low opacity, for instance. But regular filaments can also exhibit varying degrees of opacity depending on how thinly they are printed. Some objects have tapering edges, and these edges can often be more see-through than the rest of the object. Each filament brand is different.

If this is a parameter you are considering for your filament, you can quickly test the opacity of a filament by melting a small blob onto your printer bed and then using a knife to smear it. When it cools, you can hold the smeared blob up to a light source and see how much light passes through it at various thicknesses.

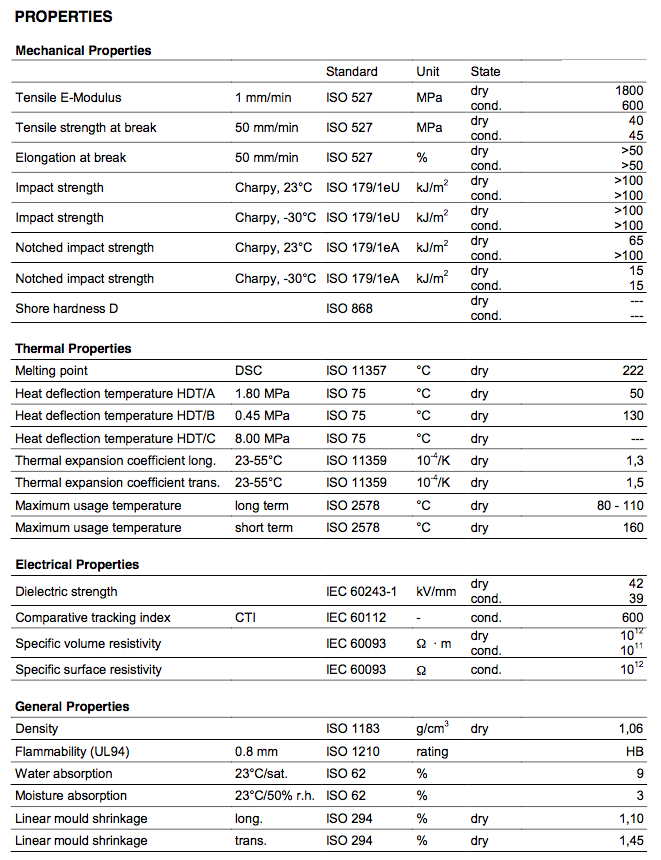

7. Technical data sheets and Material Safety data sheets

Many filament brands offer technical data sheets on their websites that have exact specifications about the material properties of their filament. These data sheets contain information such as strength, flexibility, impact resistance, and chemical composition.

This is very helpful for determining if a filament is right for your project. You can usually find these data sheets on a company’s website on product description pages.

Materials safety data sheets are also often provided by filament producers. Filament manufacturers provide safety data sheets that include information about how to safely store and use filament, the composition of the materials, flammability, and first aid advice about what to do if you ingest, inhale or otherwise come into contact with the material in an unintended and dangerous way.

Looking For A Different Term?

Check out the full Glossary of 3D Printing Terms for a complete list of 3D Printing terms, both common and uncommon. Or leave a comment with the term you are looking for and an answer will be provided.